Brazilian market leader in vacuum disc filtration for iron ore

We meet needs by offering the best solution for wet filtration and environmental protection

Who we are

Know our history

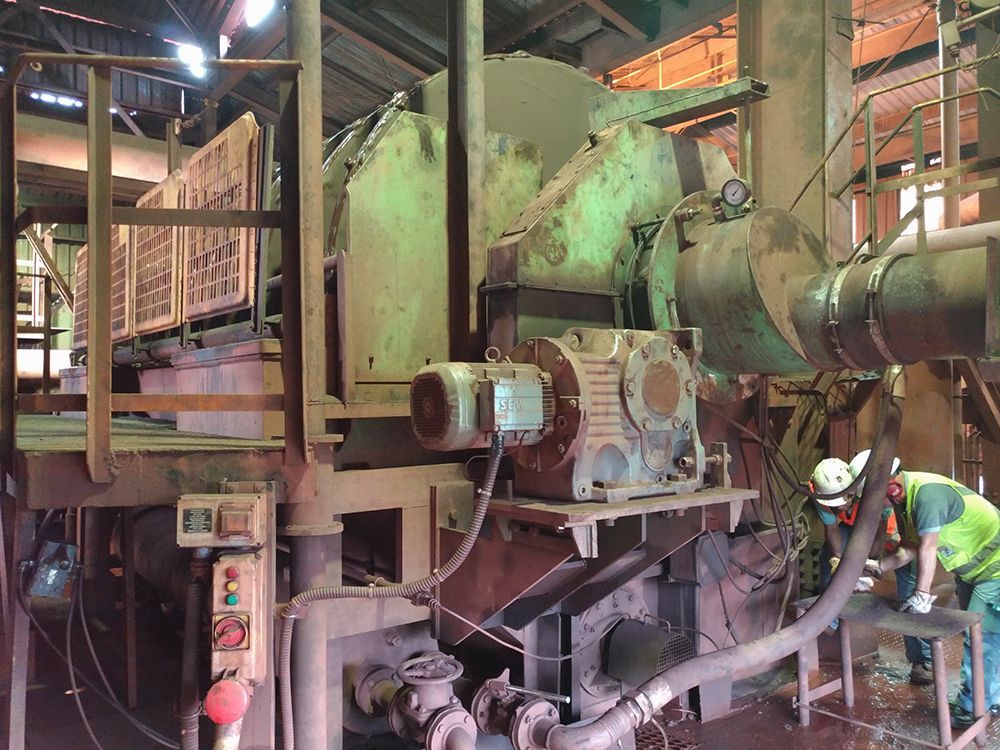

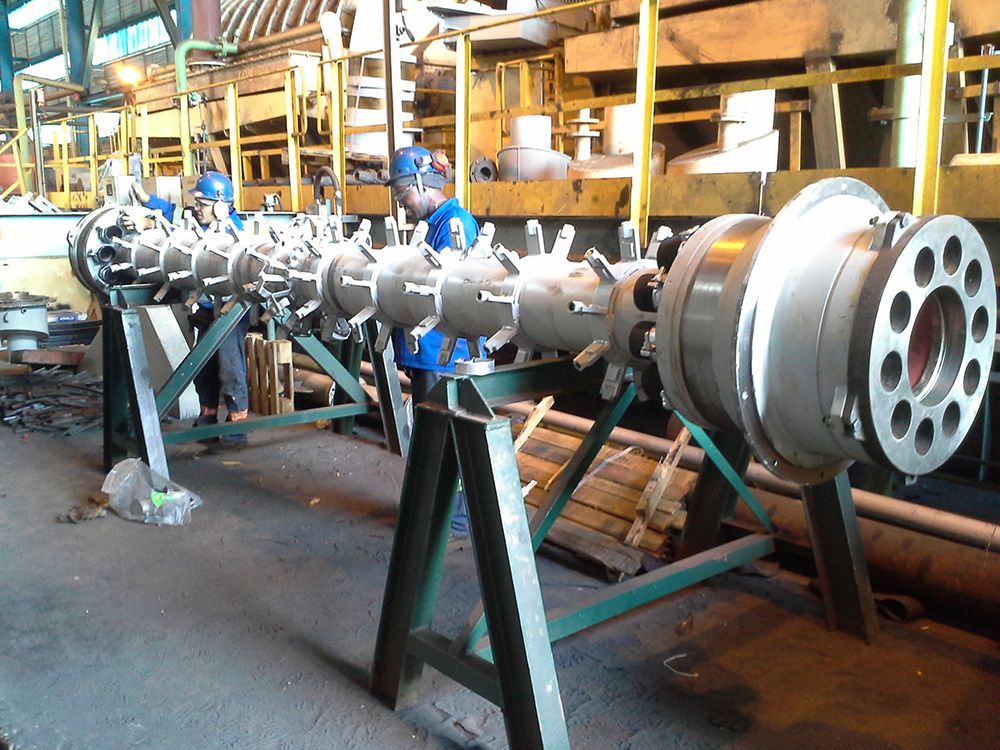

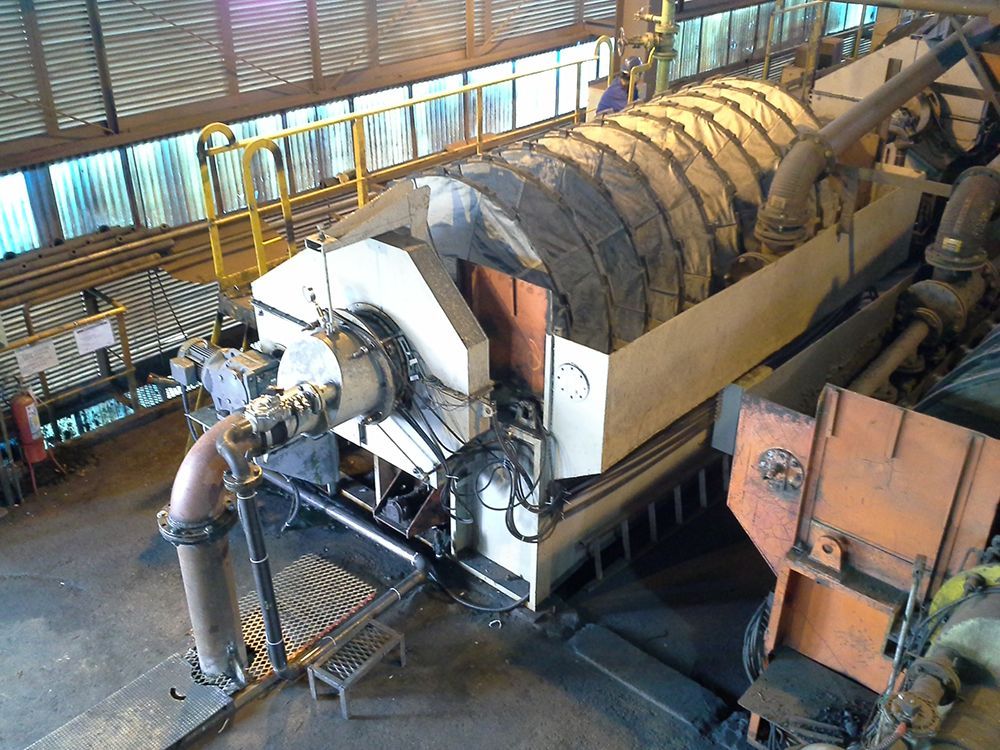

Founded in 1993, we are a company based in Belo Horizonte/MG that manufactures equipment for solid/liquid separation. We are the leader in the Brazilian market in vacuum disc filtration for iron ore and we are continuously developing products and solutions for the filtration of different products.

Always working to increase the production capacity and diversification of our products, we have developed filters with low investment and that have excellent productivity, efficiency in reducing humidity and low operating costs. In addition, we evaluate and diagnose filtration in existing and projected plants, to include improvements in their performance, aiming at an effective reduction in cost per filtered ton.

The technology developed by our company allows a better use of available labor, providing greater agility in the operations and maintenance of this equipment. The result is the quality of the filtered material and competitive costs.

Mission

Our mission is to meet the needs of our customers, offering them the best possible solution for wet filtration and environmental protection, with safe, robust, versatile and high-performance equipment.

Vision

To be a market leader in wet filtration solutions.

Values

-

Our activities are guided by the following values:

- Respect for life and the environment from which we derive our livelihood;

- Respect for the customer who deserves the best solution for their needs;

- Respect for human work and the right to fully develop the potential of each one;

- Respect for the diversity of people and the equal opportunities, regardless of origin, ethnicity, social position, religious creed, gender or sexual orientation.

Products

Get to know our products and find out how each one can guarantee the best performance for your business

services

The technology developed by our company promotes more

Agility in equipment operations and maintenance

News

How can we help you?

Get in touch with our team and learn about our solutions!

Contact

+55 (31) 3194-4700

brasfelt@brasfelt.com.br comercial@brasfelt.com.br

Rua Lecy Gomes Barbosa, 180 - Jatobá, Belo Horizonte/MG, CEP: 30664-004

Site map

Who we are

Clients

Products

Utilization

Services

News

Desenvolvido por Mobsite - Tecnologia para sites ©